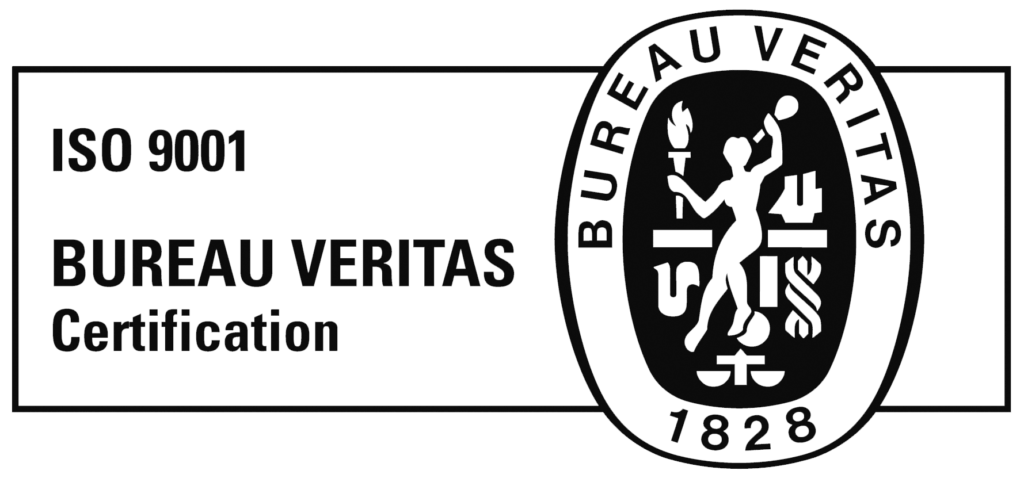

Engineering

An approach, a philosophy, values...

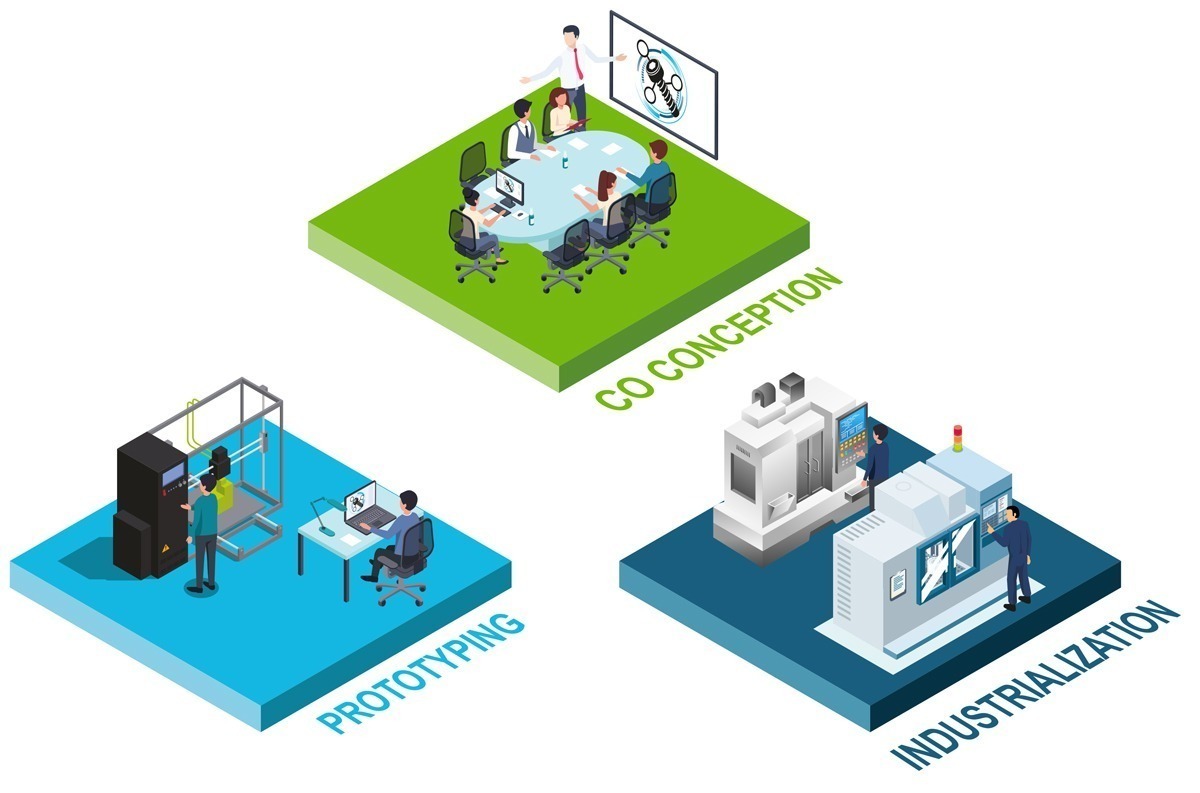

We support our clients in the development of solutions of fasteners and have particular expertise in sizing assembly systems.

SECAM and the HBP group participate in projects at an early stage with large companies such as Saint-Gobain as well as prime contractors in aviation and space, to design the bindings of tomorrow.

A very experienced team

Lucien, Doctor of Materials

expert in polymers and composites 35 years of experience

Fabien, Mechanical engineer

fasteners expert,

30 years of experience

David, Nicolas, Ronald, Yoann, 4 Technical-commercial

able to identify

all your projects

with experience

from 15 to 30 years old.

The HBP group also has 4 Mechanical Engineers and a Chemical Engineer who can come as reinforcements at any time.

CAD, finite element simulation, RDM calculations and sizing

Patent

Owner of several patents, in particular in the fixing of sandwich panels, we can assist you in the management of your Intellectual Property, in particular via a patent filing partnership.

Our means

We benefit from a network of local suppliers guaranteeing us agility and responsiveness for the realization test materials.

Traction Machine

Up to 25 kN

Piloted movement

Torque control

Controls angle and force up to 10 Nm

Torque sensors up to 200 Nm

3D printing

Volumic3D stream 30

Mechanical workshop

lathes, traditional milling machines, drills, …

Ceramics & Advanced Materials

Our Expertise in Technical Ceramics

- Study and development of ceramic formulations with specific properties

- Color development to meet your aesthetic and technical requirements

- Shaping processes: machining, pressing or ceramic coating

- Expertise in sintering, coloring, and finishing for flawless results

- Monitoring and research on innovative materials, including bio-based or recycled sources

Practical solutions driven by your ideas

Punchi®: An Innovation in Ceramic Machining

HBP Group is revolutionizing ceramic machining with Punchi®, an innovative and eco-friendly in-house process.

From powder formulation to post-sintering finishing, we deliver high-precision ceramic components tailored to demanding applications.

This method is three to four times more cost-effective than existing technologies and allows for the reintegration of machining waste into production.

With Punchi®, HBP Group strengthens its pioneering position in the field of technical ceramics while embracing a sustainable approach.

Carbonium® : technologie de pointe et durabilité

Future Materials: CMC and OCMC

HBP teams also stand out for their expertise in machining complex materials such as ceramic matrix oxides (CMC, OCMC).

These materials require a precision-based approach, especially in managing the tool-material interaction.

By integrating innovative solutions, HBP rises to the challenges of future materials, designed for the most demanding sectors (aerospace, medical, micro-mechanics).