Simple and quick manual assembly

Very sharp teeth to allow better penetration into the material

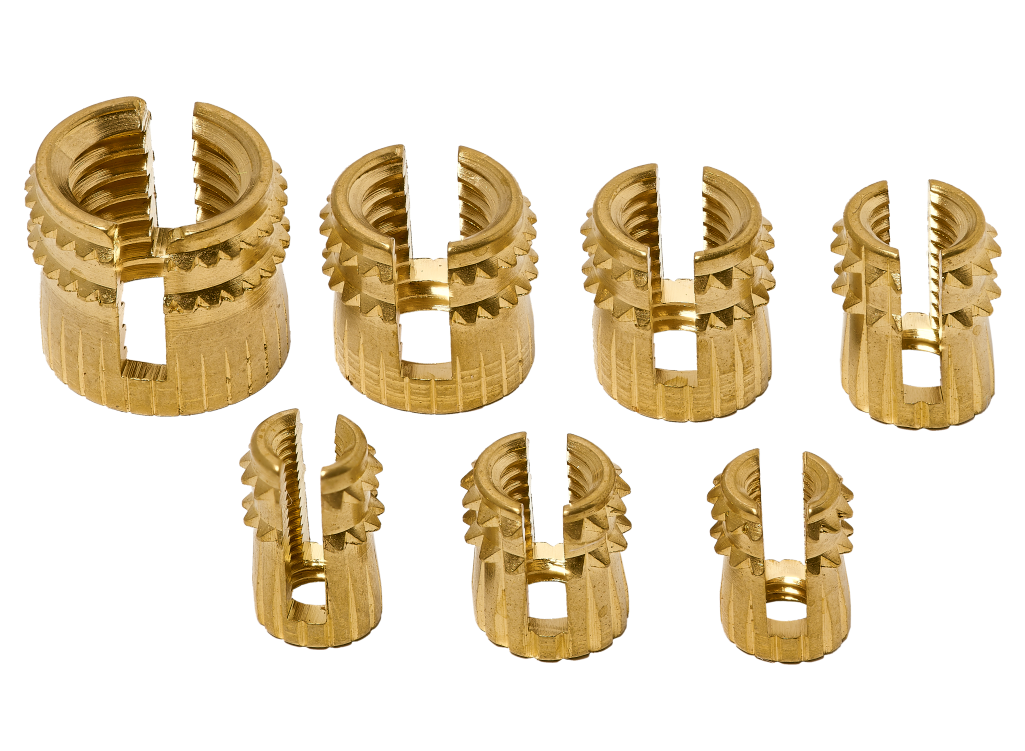

Long with two anchor crowns

Low cost

Anchorage increasing torque and pull-out resistance

- Low cost

- Simple and quick manual assembly

- Anchorage increasing torque and pull-out resistance

- Long with two anchor crowns

- Very sharp teeth to allow better penetration into the material

Técnica de fijación – Grandes series – E-Shop

| Part Number | Thread M (6H) | L (mm) | Ø E (mm) | Ø A (mm) | Ø B (mm) | Well Ø | Technical sheet | 3D |

|---|---|---|---|---|---|---|---|---|

| IE L 030 080 T056 L 0 | M3 X 0.50 | 8 | 5.6 | 5 | 4.5 | 4.60 - 4.70 | ||

| IE L 030 095 T056 L 0 | M3 X 0.50 | 9.5 | 5.6 | 5 | 4.5 | 4.60 - 4.70 | ||

| IE L 040 080 T066 L 0 | M4 X 0.70 | 8 | 6.6 | 6 | 5.4 | 5.50 - 5.60 | ||

| IE L 040 095 T066 L 0 | M4 x 0.70 | 9.5 | 6.6 | 6 | 5.4 | 5.50 - 5.60 | ||

| IE L 050 090 T076 L 0 | M5 X 0.80 | 9 | 7.6 | 7 | 6.5 | 6.60 - 6.70 | ||

| IE L 060 090 T086 L 0 | M6 x 1.00 | 9 | 8.6 | 8 | 7.5 | 7.60 - 7.70 | ||

| IE L 080 100 T106 L 0 | M8 X 1.25 | 10 | 10.6 | 10 | 9.4 | 9.50 - 9.60 |

Expansion Insert – L Type: long

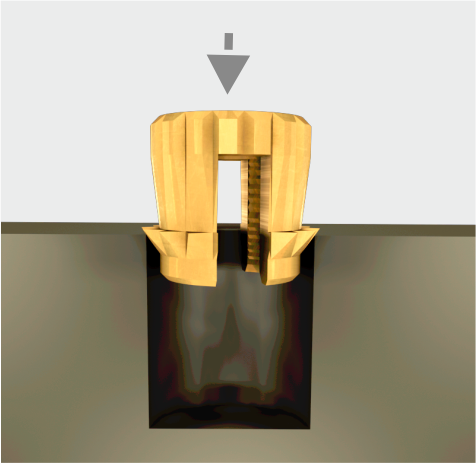

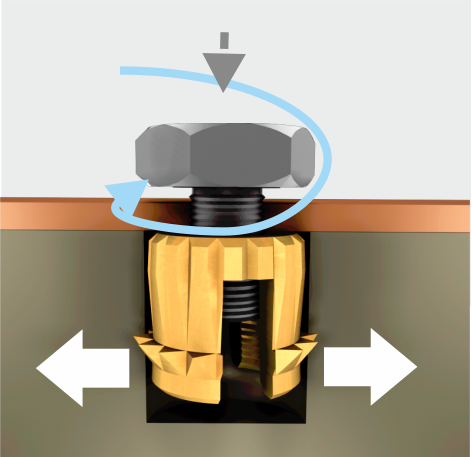

Phase

01

The insert is placed in a cavity which is either drilled or moulded in: the well.

Phase

02

The insert is forced into the well by axial pressure, deforming slightly in the process. The insert will be flush with the material to avoid possible removal due to lever effect.

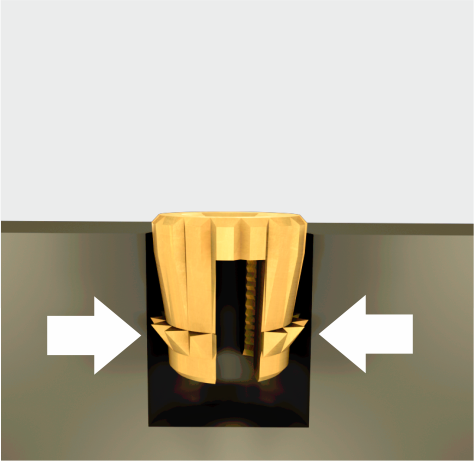

Phase

03

As the screw goes in, the insert returns to its original shape, the locking pyramids are forced into the material, providing holding force and torque resistance. Select a screw long enough to effectively force the locking pyramids into the material. The screw must never come into contact with the bottom of the well.

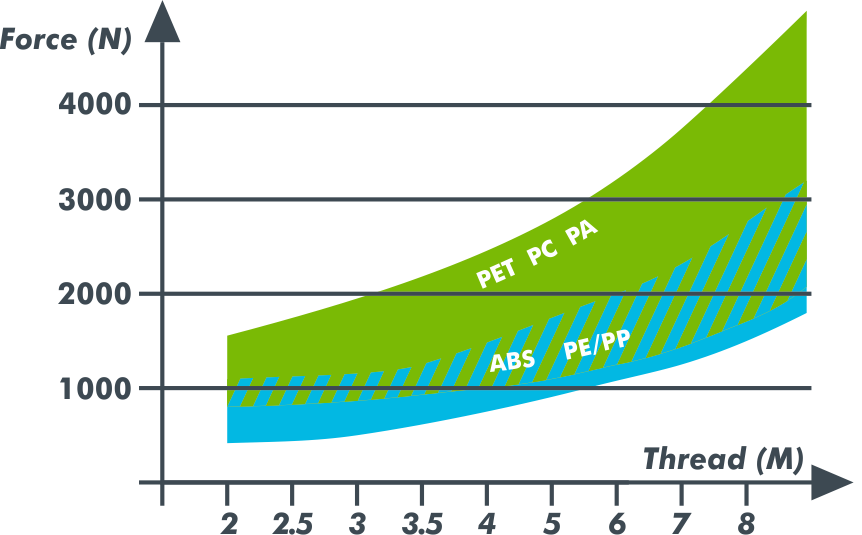

- According to laboratory tests carried out on unfilled materials

- Values given for information only

Product |

Sub-family |

Type |

Thread |

L |

Outer Shape |

Ø E |

Materials |

Specification |

|||||||

Example |

I |

E |

L |

0 |

2 |

0 |

0 |

8 |

0 |

T |

0 |

3 |

9 |

L |

0 |

|

Insert |

Expansion |

Long with 2 locking rings |

Internal thread |

Total length 8 mm |

Knurled |

Largest diameter 3.9mm (1/10mm) |

Brass CW 614N |

None |

|||||||

| Sub-families U Ultrasonic V Screw S Moulded-in E Expansion P Pressed-in |

Expansion insert type Outer shape |

Materials |

Specifications 0 none 1 ZnNi Zinc Nickel N Nickelage |