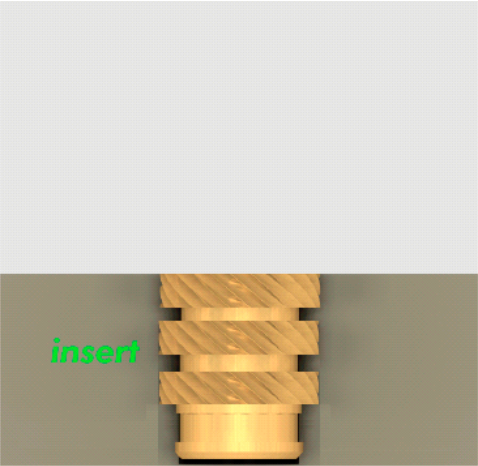

Headless

30° knurl reduces radial loads during installation

Reduction of the boss walls

Pilot tip for easier positioning

- 30° knurl reduces radial loads during installation

- Reduction of the boss walls

- Pilot tip for easier positioning

Técnica de fijación – Grandes series – E-Shop

The 3D files for this reference are available online.

Please enter your email address to receive the link to access the download platform.

You will have access to all references with the different dimensions.

| Part Number | Thread M (6H) | L (mm) | Ø E (mm) | Ø B (mm) | Well Ø (mm) | Recommended min. wall thickness (mm) | Technical sheet | 3D |

|---|---|---|---|---|---|---|---|---|

| IP 1 025 053 R042 L 0 | M2.5 X 0.45 | 5.3 | 4.2 | 3.7 | 3.8 | 2.5 | ||

| IP 1 030 053 R042 L 0 | M3 x 0.50 | 5.3 | 4.2 | 3.7 | 3.8 | 2.5 | ||

| IP 1 040 074 R058 L 0 | M4 X 0.70 | 7.4 | 5.8 | 5.3 | 5.4 | 2.7 | ||

| IP 1 050 083 R066 L 0 | M5 x 0.80 | 8.3 | 6.6 | 6.1 | 6.2 | 3 | ||

| IP 1 060 092 R082 L 0 | M6 X 1.00 | 9.2 | 8.2 | 7.7 | 7.8 | 3.4 | ||

| IP 1 080 092 R097 L 0 | M8 x 1.25 | 9.2 | 9.7 | 9.3 | 9.4 | 3.8 |

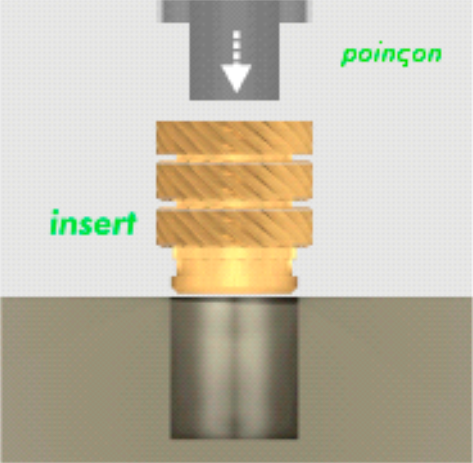

Pressed-In Insert – Type 1: unheaded

Phase

01

Push in the insert, preferably with a press, not a hammer.

The insert is forced into a hole, without impact or bouncing, by axial pressure in a press with a punch.

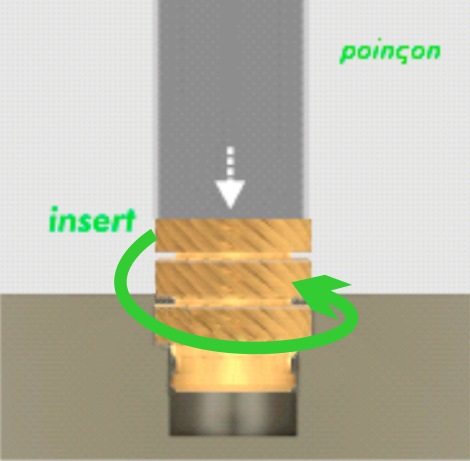

Phase

02

The insert rotates slightly in the direction of the knurling. The punch must be smooth to allow the insert to rotate.

The insert must be held axially, since any inclination will result in radial loads which may damage the material.

Phase

03

Le plastique sous effet de l’insert se déforme pour fluer dans le profil spécifique de l’insert et ainsi permettre une bonne tenue au couple et à l’arrachement.

Product |

Sub-family |

Type |

Thread |

L |

Outer Shape |

Ø E |

Materials |

Specification |

|||||||

Example |

I |

P |

1 |

0 |

2 |

5 |

0 |

5 |

3 |

R |

0 |

4 |

2 |

L |

0 |

|

Insert |

Pressed-in |

Headless |

Internal thread |

Total length 5.3 mm |

Round |

Largest diameter 4.2mm (1/10mm) |

Brass CW 614N |

None |

|||||||

| Sub-families U Ultrasonic V Screw S Moulded-in E Expansion P Pressed-in |

Pressed-in insert type Outer shape |

Materials |

Specifications 0 none 1 ZnNi Zinc Nickel N Nickelage |