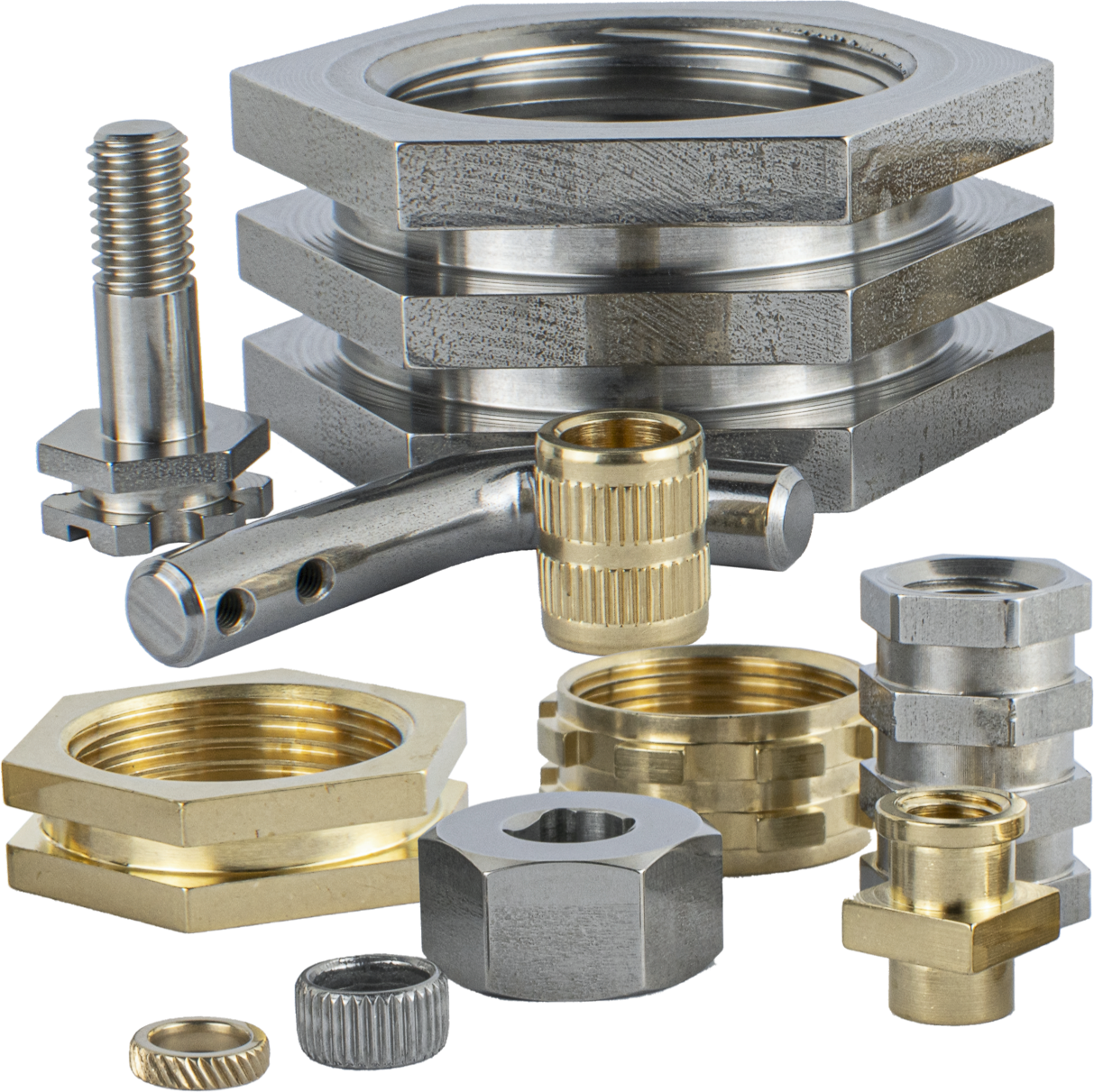

Customized according to drawing

Special inserts manufactured to specification

Custom inserts made to drawing

A tailor-made technical solution

Each industrial project presents its own mechanical, geometric or aesthetic constraints. To meet these specific requirements, SECAM designs and manufactures custom inserts made to drawing, fully tailored to your part or assembly process.

Whether you need a moulded-in insert with a custom shape, a screw-in insert for a tight space, or a technical insert in a specific material (stainless steel, aluminium, reinforced brass), our engineering team supports you from functional analysis to serial delivery.

A co-design approach with our engineering office

The development of a custom insert begins with a listening and analysis phase. Our engineers work directly with your design team to understand:

- Mechanical constraints (tension, compression, vibrations, shear…)

- Assembly conditions (moulding, overmoulding, screwing, heat insertion…)

- Materials used in the part (plastic, resin, metal, wood…)

- Acceptable tolerances and dimensions

- Target production volumes

With strong expertise in fastening engineering, SECAM provides you with technical, cost-effective and industrial solutions.

When should you consider a custom insert?

Custom inserts are recommended when standard ranges do not meet a critical constraint. Typical cases include:

- Special shapes to fit into non-standard cavities

- Precise dimensions not covered by standard product lines

- Enhanced sealing or specific surface treatments

- Assembly in composite or technical materials

- High-value parts requiring hidden or flush-fastening

Our goal: to design an insert fully integrated into your product – without unnecessary cost or complex adaptation of your tools or processes.

Full support from prototype to production

SECAM supports you at every stage:

- Needs analysis and technical feasibility

- 3D design and insert modelling in its environment

- Rapid prototyping via machining or metal 3D printing

- Performance testing (pull-out, torque, ageing)

- Series production with material and dimensional quality control

This rigorous process ensures an insert that meets your expectations, even for medium or low volumes.

Custom inserts for every type of installation

Our made-to-drawing inserts can be designed for all processes:

- Overmoulded: custom geometry for maximum grip in injection moulded plastics (see standard range)

- Screw-in after moulding: custom thread and knurl for enhanced pull-out performance (view our screw-in models)

- Press-fit, heat, or ultrasonic: inserts optimised for automatic insertion

- Expansion type: ideal when access is limited

We adapt geometry, thread type, material and surface finish to your specific constraints.

Available materials and custom options

Our custom inserts can be manufactured in a wide range of materials:

- Standard or high-performance brass

- Zinc-plated or stainless steel

- Technical aluminium

- Bi-material inserts or with built-in secondary components

Surface or heat treatments can be added to enhance corrosion resistance, friction behaviour, or other technical properties.

Examples of custom insert applications

SECAM’s bespoke inserts are used in demanding sectors:

- Automotive: sensors, interior trim, structural assemblies

- Electronics: connected housings, component mounts

- Medical: single- or multi-use devices requiring sealing

- Furniture: invisible fasteners for design-driven parts

- Plastic industry: technical overmoulding, shrink-sensitive parts

Our ability to produce reliable inserts in small and medium batches makes SECAM a trusted partner for complex projects.

Engineering expertise at the service of your performance

For over 50 years, SECAM has developed strong expertise in fastening solutions for plastics, composites and light alloys. Thanks to our in-house design office and industrial partners, we deliver ready-to-use custom inserts that meet your quality and compliance requirements.

Contact us for your custom projects

Do you need to equip a complex part with a threaded insert? Looking to improve the mechanical strength of your assembly? Our team supports you in defining and designing your made-to-drawing insert.

👉 Contact us now to discuss your project.

With SECAM, turn your ideas into reality with 100% custom-engineered inserts.

Contact us

Do you have a technical or commercial question?

Leave us your contact details so we can get back to you.

You can also write to us or call us directly.

FAQ – Inserts spécifiques sur plan

What is a custom insert made to drawing?

A custom insert is a fastening element specifically designed to meet your mechanical, dimensional, or aesthetic requirements. Based on a technical drawing or functional analysis, SECAM manufactures inserts tailored to your part or assembly process.

Why choose a made-to-drawing insert?

Standard inserts may not fit in complex geometries or meet specific technical constraints. A made-to-drawing insert ensures perfect integration without compromising performance or requiring mold/tool modifications.

Which materials can be used?

Custom inserts can be made from:

- High-performance brass

- Stainless or zinc-plated steel

- Technical aluminium

- Multi-materials or combined metal inserts

For which applications are custom inserts used?

SECAM custom inserts are widely used in:

- Automotive (structural parts, interior trims)

- Electronics (sensor housings, PCB supports)

- Medical devices (hermetic or removable assemblies)

- Design furniture (invisible fixings)

- Plastics industry (overmoulded technical parts)

How does the development process work?

SECAM supports you step by step:

- Requirement analysis and feasibility

- 3D design and modeling

- Prototyping (machining or metal 3D printing)

- Mechanical testing (pull-out, torque, ageing)

- Serial production and quality control

Can I request a prototype or small batch?

Yes. We produce small and medium series, and offer rapid prototyping to validate the design before tooling or full production.

Which types of assembly are supported?

Custom inserts can be designed for:

- Overmoulding

- Screw-in (post-moulding)

- Press-fit, heat staking, or ultrasonic insertion

- Expansion or self-locking applications

How to request a quote for a specific insert?

Send us your drawing, material specifications, assembly type, and production volume. Our team will analyze your needs and propose a suitable solution.

Contact us.