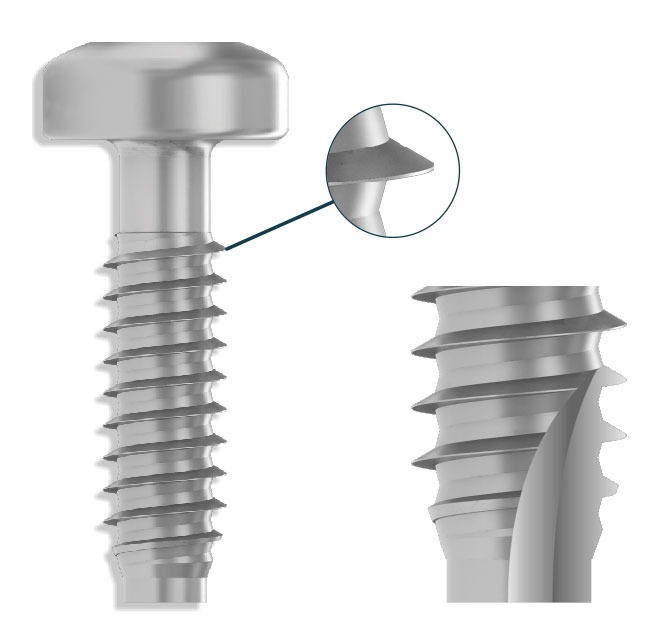

Asymmetrical 30° thread self-tapping screw for thermosets & light alloys

Asymmetrical

30° thread

Cutting slot optional

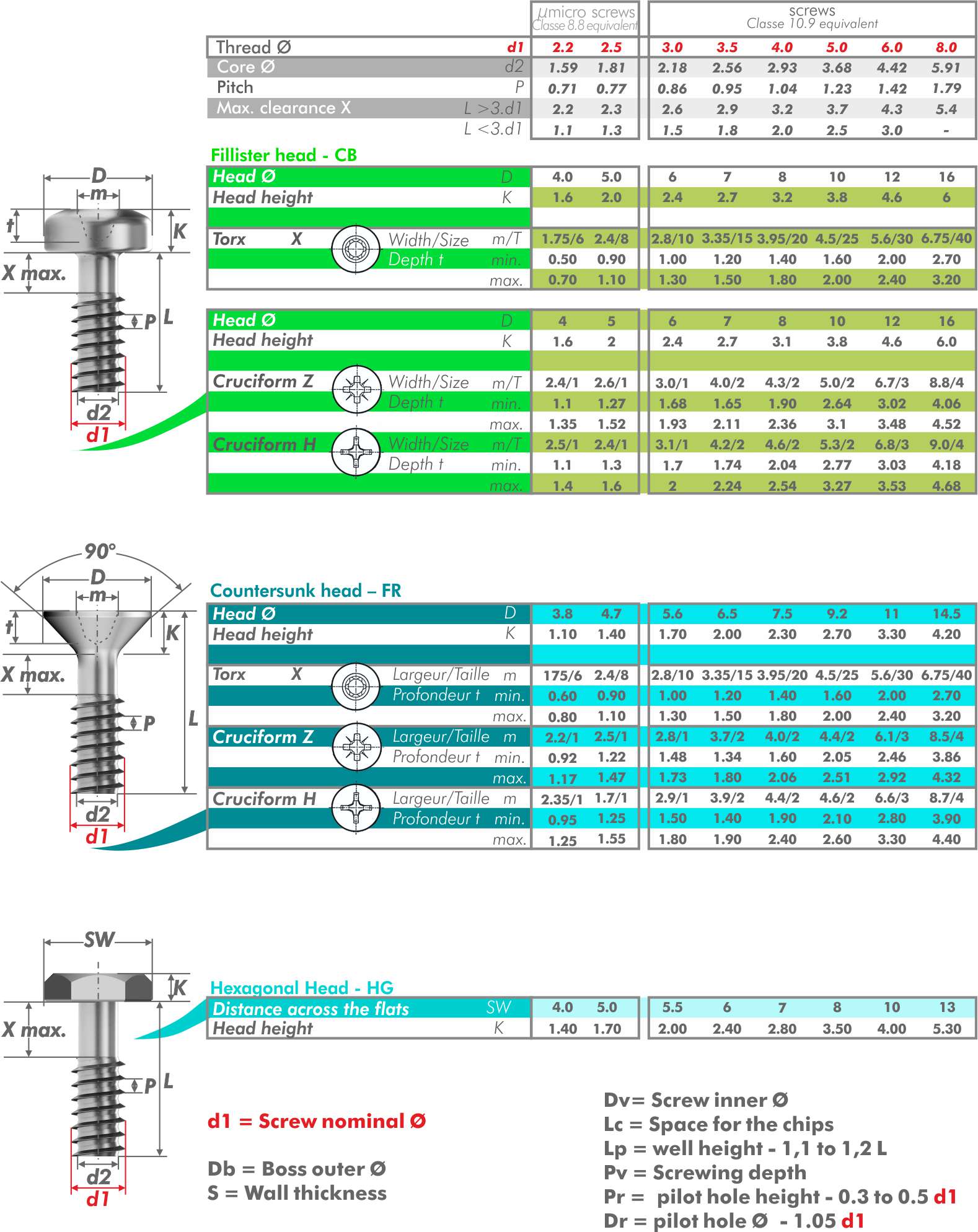

Dimensions

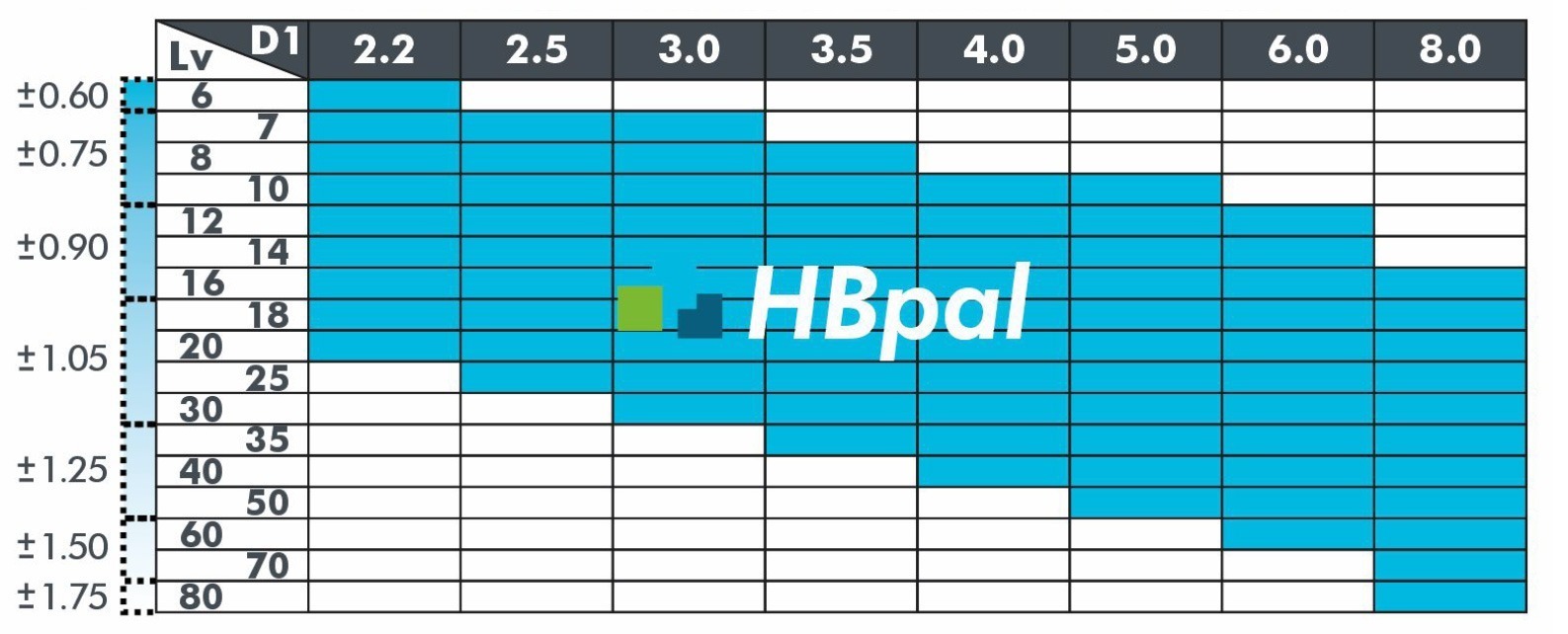

Manufacturing programme

For countersunk heads, add 2 mm to the length.

Valeurs en mm

Code Reading

Assembly recommendations

The thread is formed by heating the plastic. We recommend using an electric or

pneumatic screwdriver.

A speed of between 500 and 600 r.p.m. is required in thermoplastics and

between 300 and 1000 r.p.m. in light alloys

Excessive speed may damage the material and destroy the thread.

Screw drives

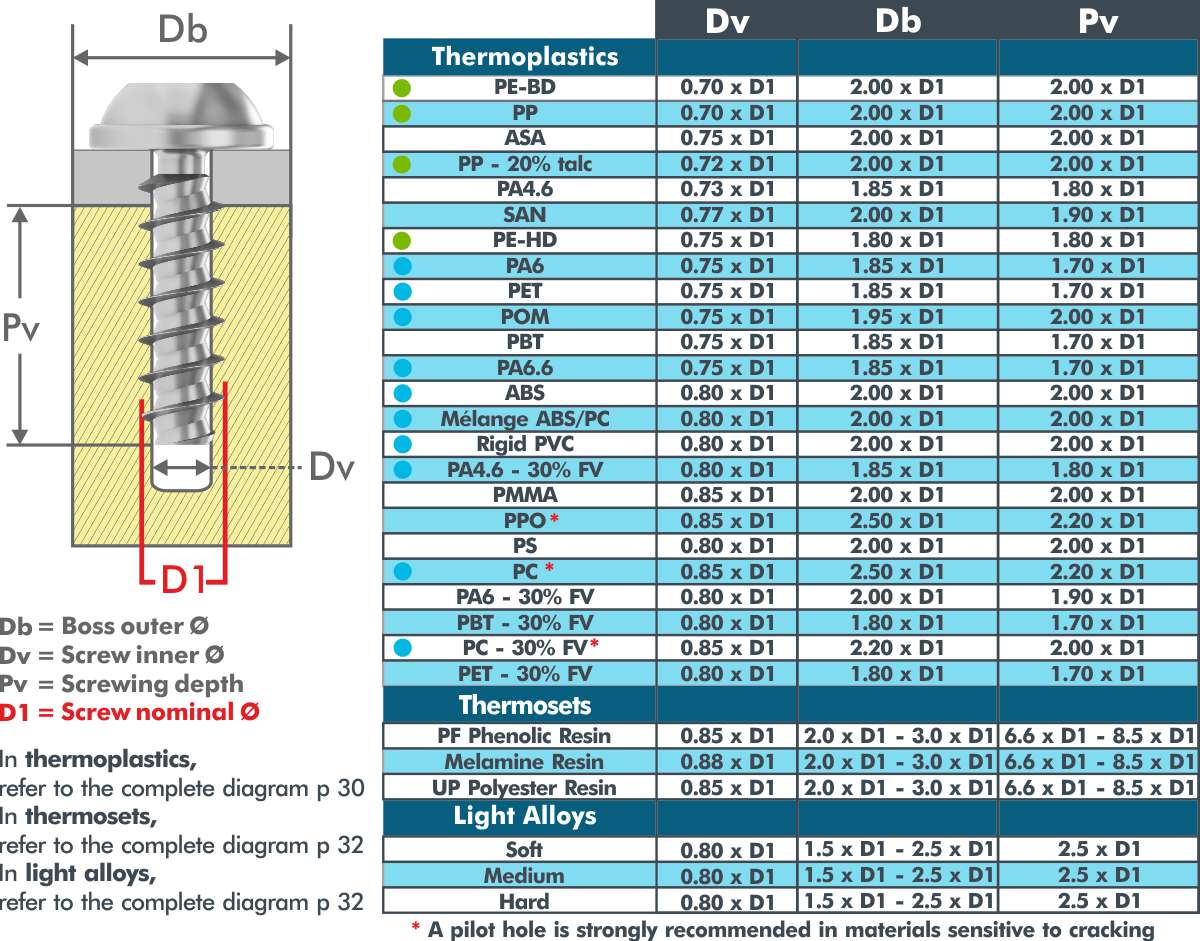

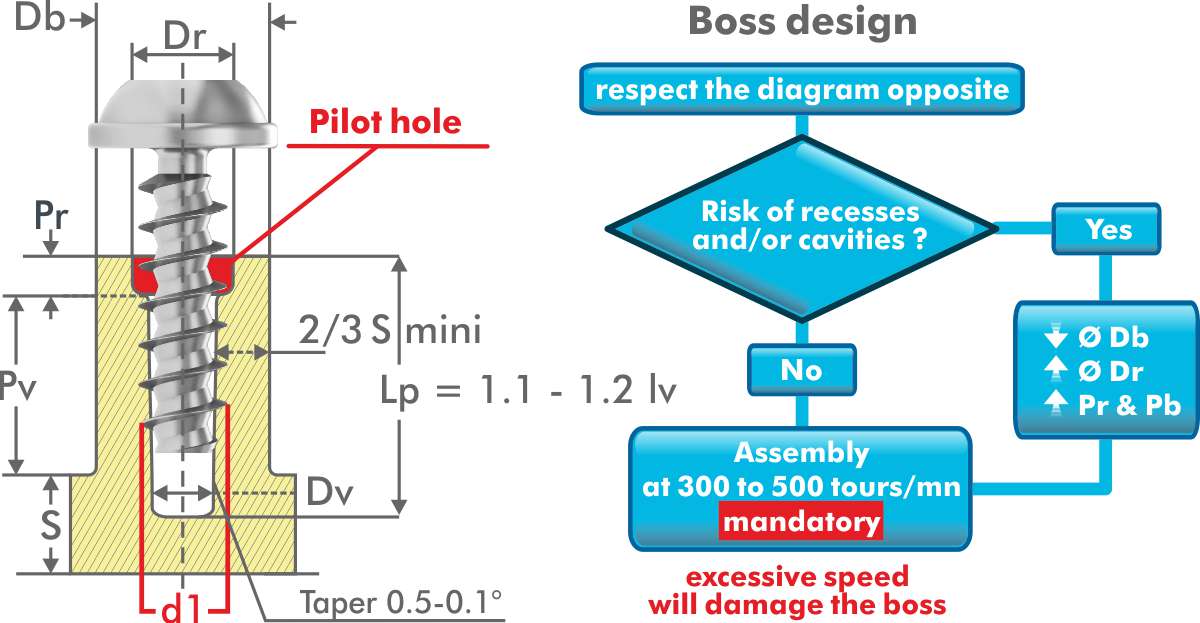

Boss Design

How to fix

Screw drives

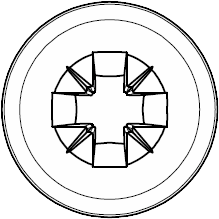

Advantages of the torx drive

- Increases the torque transmission

- Limits the tool pressure on the screw

- No slipping of the tool in the screw drive

- Reduces wear on the screw drive

and the screwdriver - Suitable for all types of screw

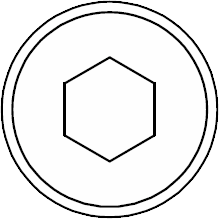

Hexagonal socket

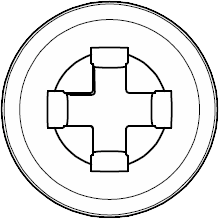

Cruciforme Z

Pozidrive

Cruciforme H

Phillips

Self-Tapping Screw with 30° Asymmetric Thread for Thermosets

Advantages

- High resistance to vibration & pull-out

- Hard thermoplastics & thermosets

- Lightweight alloys (Aluminum, Magnesium, …)

- Increased pull-out strength

- Cutting slot option

- 30° thread

Manufacturing Program

Add 2 mm to the length for countersunk heads.

Values in mm

Assembly Recommendations

The thread forms through plastic heating. We recommend using an electric or pneumatic screwdriver.

The rotational speed should be between 500 and 600 RPM in lightweight alloys.

Too high a speed can damage the material and ruin the threading.

Advantages of the 6-Lobe Drive

- Increases torque transmission

- Reduces tool pressure on the screw

- No tool slipping in the drive

- Reduces wear on the screw drive and assembly tool

- Adaptable to all screw types

- 6-point hex

- Cruciform Z

- Cruciform H

Self-Tapping Screws for Plastics and Lightweight Alloys

30° asymmetric threading for high-performance fastening.

Self-tapping screws are fastening elements designed to create their own thread directly in the material without pre-tapping. At SECAM Fixation, the 30° asymmetric-thread self-tapping screw has been specially developed to provide excellent mechanical strength in technical plastics (thermosets, hard thermoplastics) and lightweight alloys such as magnesium or aluminum.

Enhanced Performance for Reliable Assemblies

The specific asymmetric thread geometry allows progressive penetration into the material, reducing stress on the boss while improving pull-out and vibration resistance. This innovative design ensures durable fastening without needing an insert or prior tapping.

- Suitable for rigid plastics (thermosets, hard thermoplastics)

- Compatible with lightweight alloys like aluminum or magnesium

- 30° asymmetric threading for precise tightening

- Cutting slot option for easier starting

- High mechanical resistance to pull-out and shear

This type of screw is ideal in applications where mechanical stresses are high: embedded electronics, automotive, connectors, etc.

Applications of Self-Tapping Screws

SECAM self-tapping screws are used in many industrial sectors to ensure robust and long-lasting assemblies:

- Automotive industry: fastening plastic components in door panels, dashboards, or structural elements.

- Electronics: fastening circuit boards, technical enclosures, or power modules.

- Industrial equipment: mechanical assemblies in rigid plastic or aluminum parts.

Assembly Recommendations

The self-tapping screw forms its own thread by mechanical or thermal effect. It is recommended to use an electric or pneumatic screwdriver at moderate speed to preserve the material.

- Recommended speed: between 500 and 600 RPM in lightweight alloys

- Avoid excessive speed to prevent thread damage

- Provide a boss diameter adapted to the screw geometry

Careful boss design ensures optimal anchoring and extended assembly lifespan. For detailed technical recommendations, consult our SECAM engineering office.

Available Drives

Our self-tapping screws are available with several drive types to suit your production needs:

- 6-lobe drive: high torque transmission, no slipping, low pressure on the screw.

- 6-point hex: precision and security for technical applications.

- Cruciform Z (Pozidriv) and Cruciform H (Phillips): easy-to-use industrial standards.

Each drive is designed to reduce tool wear and improve assembly repeatability in series production.

Dimensional Characteristics

SECAM self-tapping screws are available in a wide range of sizes. For countersunk heads, add 2 mm to the standard length. All dimensions are in millimeters and detailed in our manufacturing program.

A reference decoding guide is available on request for correct interpretation of our references.

Need Technical Support or a Sample?

SECAM supports you in choosing the right screw for your project. Thanks to our expertise in plastics and assembly, we advise you on the best screw/material combinations.

Contact our team via the contact page, or discover our full range of screws and inserts on the fastening page.

Complete Your Solution with Our Other Products

Looking for alternative solutions for other types of plastics? Also check out our self-forming screws, designed for flexible thermoplastics, or visit our dedicated engineering page for custom development.

Contact us

Do you have a technical or commercial question?

You can also write to us or call us.

FAQ – Self-Tapping Screws for Plastics and Lightweight Alloys

What is a self-tapping screw?

A self-tapping screw is designed to create its own thread in the material during screwing. It is especially used in rigid plastics (thermosets) and lightweight alloys like aluminum or magnesium. Its 30° asymmetric thread allows precise insertion, limiting pull-out risks and ensuring reliable mechanical strength.

What is the benefit of the 30° asymmetric thread?

The 30° asymmetric thread provides better force distribution during screwing. It improves pull-out resistance, reduces pressure on the boss, and increases assembly reliability. This thread type is particularly suitable for hard or brittle materials like thermosets.

Is pre-drilling required?

Yes, pre-drilling is generally required. The hole diameter must be precisely adapted to the screw for effective tapping without cracking the material. Pre-drilling dimensions are indicated in the technical guide provided by SECAM.

Which materials are suitable for these screws?

- Hard thermoplastics: POM, reinforced PA, PC

- Thermosets: phenolic, epoxy, polyester resins

- Lightweight alloys: aluminum, magnesium

What are the installation recommendations?

Optimal installation is done with an electric or pneumatic screwdriver at controlled speed, between 500 and 600 RPM. It is important not to exceed this speed to avoid excessive heating of the material, which could alter threading and weaken the assembly.

Which drive types are available?

- 6-lobe: high torque transmission, no slipping

- 6-point hex: precision and reliability

- Cruciform Z (Pozidriv) or H (Phillips)

Can self-tapping screws be reused?

Yes, but it depends on the material. Self-tapping screws generally allow 5 to 10 removals without major performance loss. For assemblies subjected to many cycles, SECAM recommends use of post-mould inserts to preserve the threaded housing.

Where can I find more information?

You can explore our full range on the dedicated page: Self-tapping screws for plastics.

Contact our team for any specific request or technical support.