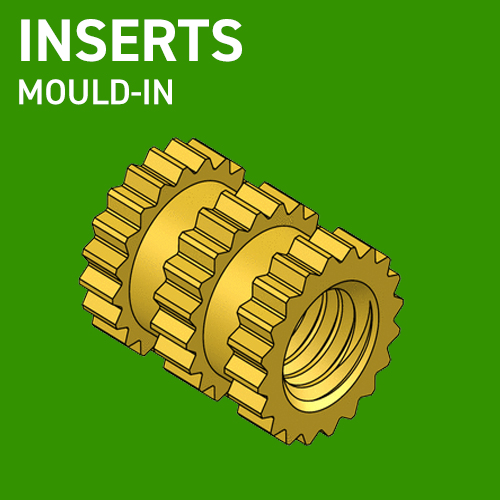

Mould-in inserts

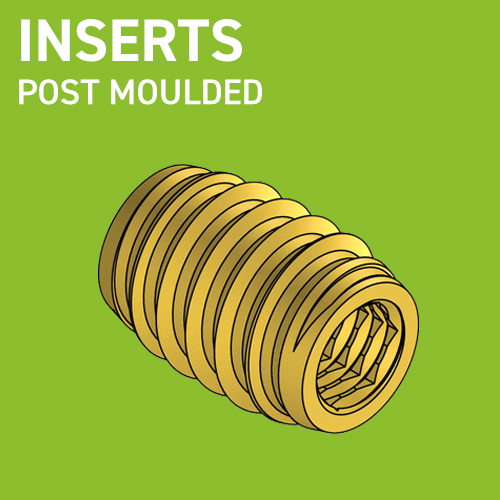

Post molding inserts for plastics, light alloys and wood.

Suitable

Suitable  Conditionally suitable

Conditionally suitable  Not suitable

Not suitable

Values are indicative. Each material is specific and has its own characteristics.

Contact us for advice

on choosing your insert

Do you have a technical or commercial question?

You can also write to us or call us.

Moulded-in inserts

Technical fastening for plastics and light alloys

Moulded-in inserts are fastening elements specifically designed to be integrated directly into the part during the moulding of plastic components, resins or light alloys. They provide high mechanical strength, excellent pull-out resistance and durable anchoring, even in demanding environments.

SECAM offers a full range of brass moulded-in inserts with several geometries (hexagonal, knurled, blind or through), tailored to the needs of injection moulders and the automotive, electronics, connectivity and furniture industries.

Why choose moulded-in inserts?

- Direct fastening within the plastic part during manufacturing

- Optimal mechanical performance with no pull-out risk

- Time savings by eliminating post-assembly steps

- A cost-effective, reliable solution for large-volume production

Inserts are also available in versions for post-mould installation, depending on the application.

Post-mould inserts for plastics, wood and light alloys

In addition to moulded-in inserts, SECAM supplies a dedicated range of post-mould inserts or inserts for other materials such as wood or light alloys. These inserts are installed mechanically (by pressing, screwing or ultrasound) into an existing part to add a fastening function or a reinforced threaded zone.

Selection depends on the substrate material, expected mechanical loads and the planned assembly process.

Moulded-in insert selection guide

Choosing an insert depends on several criteria:

- Material type (thermoplastic, thermoset, light alloy)

- Insert configuration: blind (sealed) or through

- Outer shape: hexagonal or knurled

- Mechanical constraints (tensile load, tightening torque, vibration…)

- Dimensions of the moulded part and insertion zone

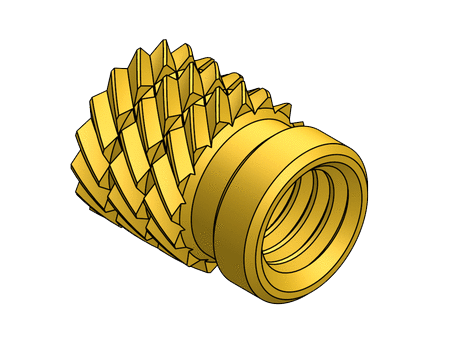

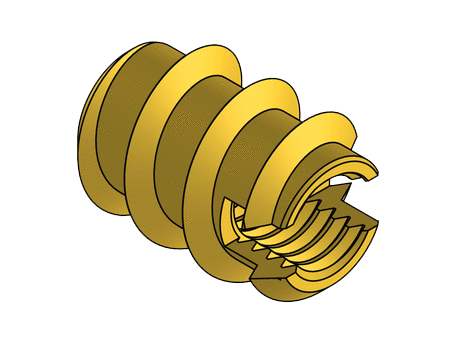

Hexagonal moulded-in inserts

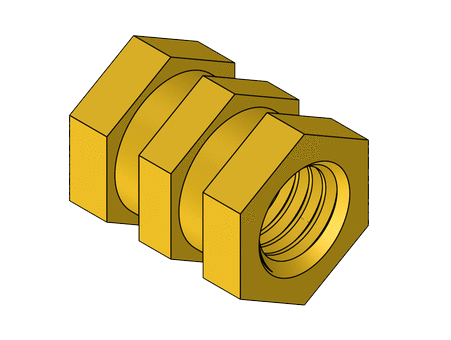

Brass hexagonal moulded-in through insert (ISD)

The hexagonal through version delivers excellent mechanical performance thanks to its anti-rotation geometry. It is suitable for injection-moulded plastic parts requiring a through threaded joint. The ISD insert is ideal for long-screw assemblies or internal mechanical connections.

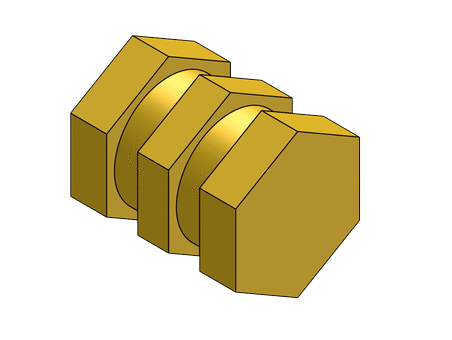

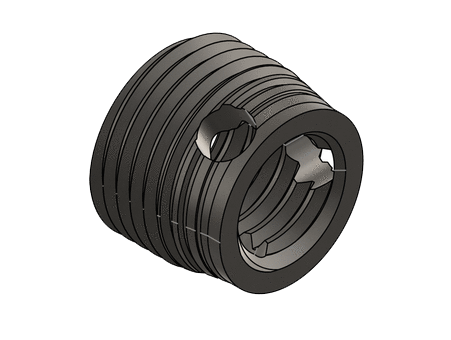

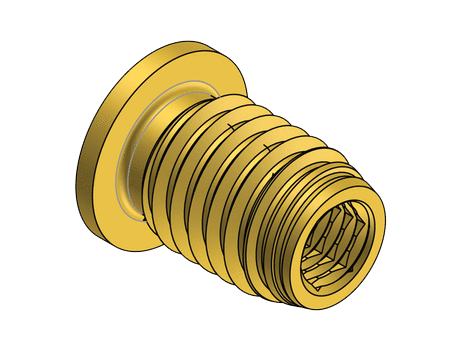

Brass hexagonal moulded-in blind insert (ISB)

The hexagonal blind version prevents the thread from passing through, ensuring complete sealing. It is used where the screw must bottom out, notably for visible assemblies or components exposed to moisture.

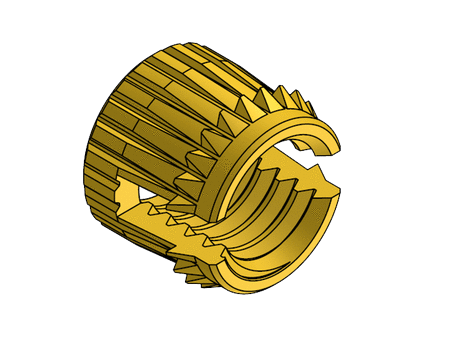

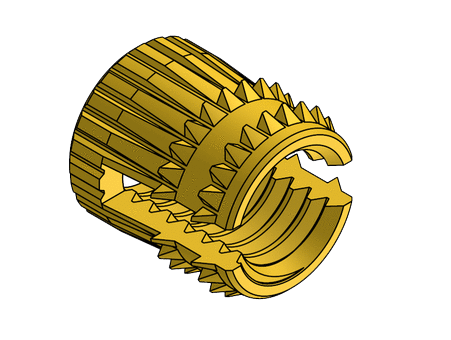

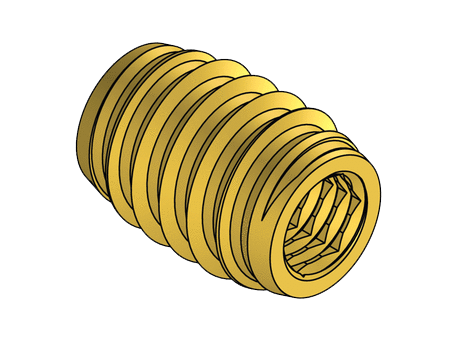

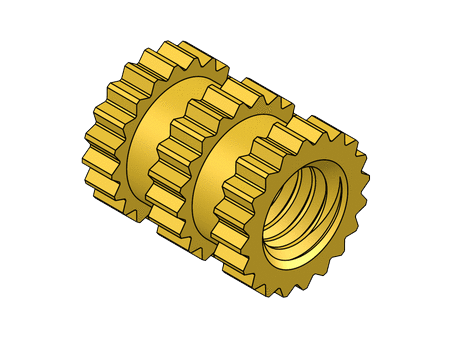

Knurled moulded-in inserts

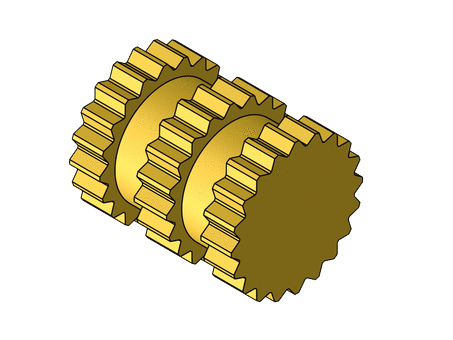

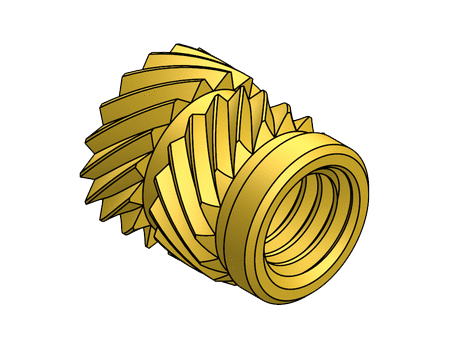

Brass knurled moulded-in through insert (ISD)

The knurled through model features fine surface grooves to optimise mechanical grip in the molten material. This insert is used for through-thread applications requiring good tensile strength without the need for a hexagonal shape.

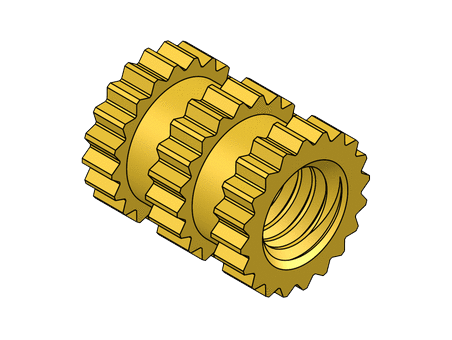

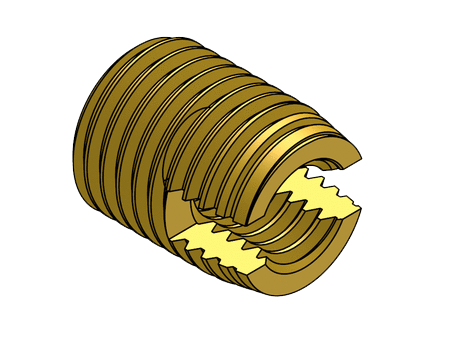

Brass knurled moulded-in blind insert (ISB)

The knurled blind version combines discretion and performance. It is ideal for internal fixings in electronic or aesthetic products where the insert must not be visible from the outside and must not allow the screw to pass through.

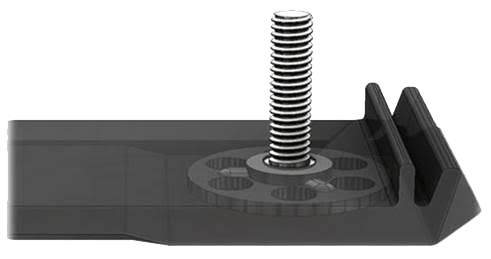

Special applications: S-Plate insert

SECAM S-Plate moulded-in insert

The S-Plate is a flat insert widely used on planar or thin surfaces. It enables a flush assembly without deforming the part. Popular in furniture, automotive and technical plastics, it offers an alternative to direct tapping in the moulded part.

Technical inserts for all your injection projects

SECAM supports manufacturers in selecting and integrating fastening solutions, from the design phase to re-engineering of existing parts. All inserts are made of high-quality brass, providing optimal corrosion resistance and excellent thermal and electrical conductivity.

Whether you need a standard or custom moulded-in insert, our engineering team will guide you to the product best suited to your application, moulding constraints and operating conditions.

Need advice on our moulded-in inserts?

Hesitating between a hexagonal or knurled version? Looking for a reliable technical solution for injection-moulded plastic parts or prototypes? Don’t hesitate to contact the SECAM team. We provide our expertise and stock of available references to meet your needs quickly, in small or large series.

Optimise the strength, reliability and quality of your assemblies with SECAM moulded-in inserts.

Contact us

Do you have a technical or commercial question?

Leave us your contact details so that we can get back to you.

You can also write to us or give us a call.que nous puissions vous répondre.

Vous pouvez également nous écrire ou nous téléphoner

FAQ - Mould-in inserts and fasteners for plastics

What is SECAMnida®?

SECAMnida® is an innovative fastening solution designed for honeycomb sandwich panels. It enables fast, reliable, and durable installation thanks to a mechanical crimping system and a patented visual fill indicator. This solution optimizes mechanical performance while reducing installation time.

What are the advantages of crimping with SECAMnida®?

Crimping ensures immediate and secure anchoring of the insert into the panel skin, with no risk of tilting before or during adhesive injection. It replaces fragile adhesive tabs used in traditional inserts, improves assembly reliability, and allows immediate handling of the panel after installation.

Which materials are compatible with SECAMnida®?

SECAMnida® is compatible with sandwich panels featuring skins made of aluminum, stainless steel, or steel. It supports panel thicknesses from 8 to 40 mm and skin thicknesses from 0.5 to 2 mm. It is ideal for applications in aerospace, rail, and automotive sectors.

How is SECAMnida® installed?

Installation involves three simple steps:

- Panel drilling

- Cold-form crimping of the insert

- Two-component adhesive injection up to the visual fill indicator

This process replaces the 7 steps required for NAS inserts and reduces installation time by a factor of four.

What are the benefits for industrial production?

With its fast installation (30 seconds), immediate handling, and visual fill control, SECAMnida® improves productivity, quality, and traceability. The process can also be fully automated using robotics developed in partnership with GEBE2.

Can SECAMnida® be installed automatically?

Yes. SECAM and GEBE2 have co-developed a robotic system capable of drilling, crimping, injecting, and controlling each step of the process. It ensures high repeatability, automated quality control, and full traceability in industrial settings.

How can I verify correct adhesive filling?

SECAMnida® features a patented visual indicator that clearly shows the fill level of the adhesive inside the panel. This guarantees a complete fill and prevents bonding issues, ensuring high-quality and consistent assemblies.

What alternatives exist to SECAMnida®?

SECAM also offers other fastening solutions for composites and sandwich panels:

- SECAM Autofix® – Bonded fastener with fill indicator

- S-Plate – Standard range of bonded inserts

For tailored support, feel free to contact our team.