Inserts post moulded

Inserts post moulage pour plastiques, alliages légers et bois.

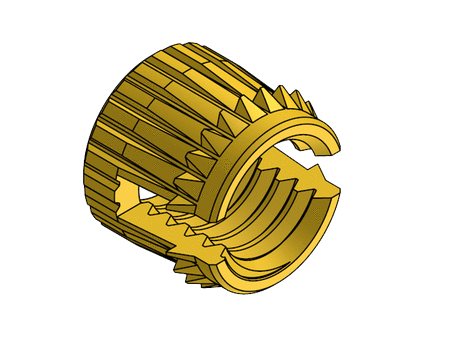

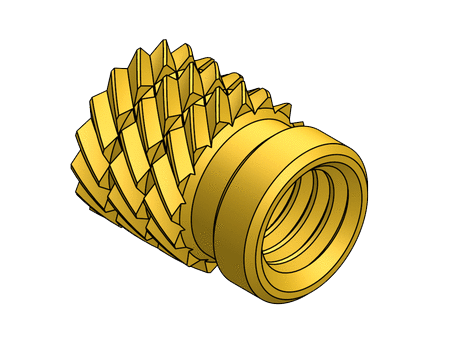

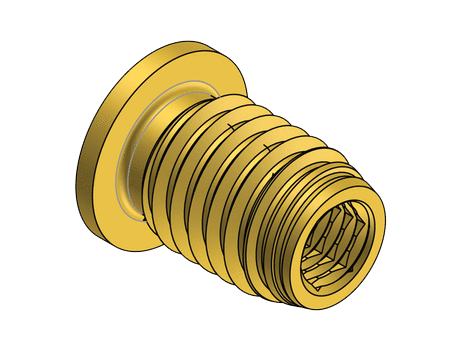

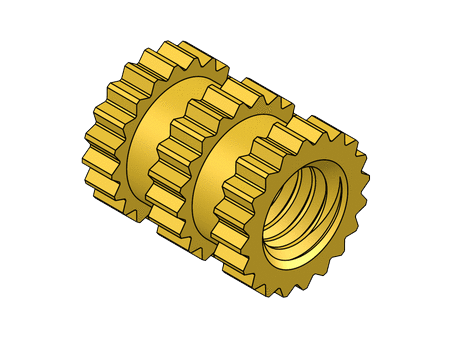

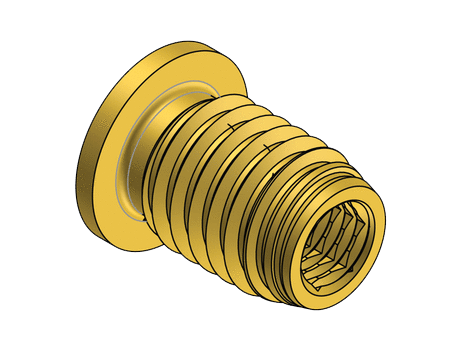

IVK

Brass threaded insert to be screwed in, with head

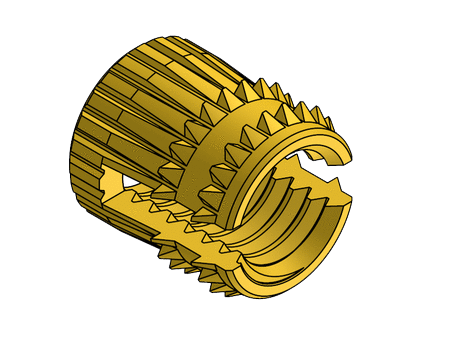

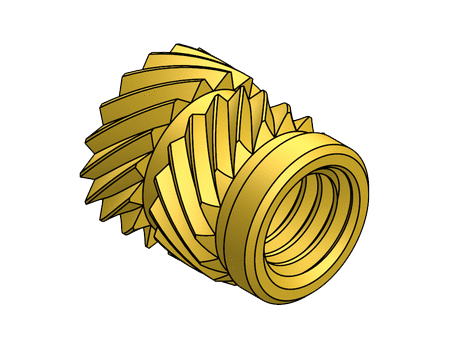

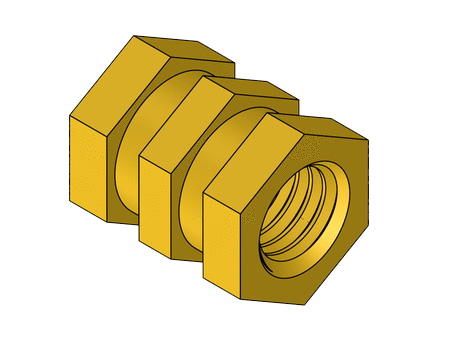

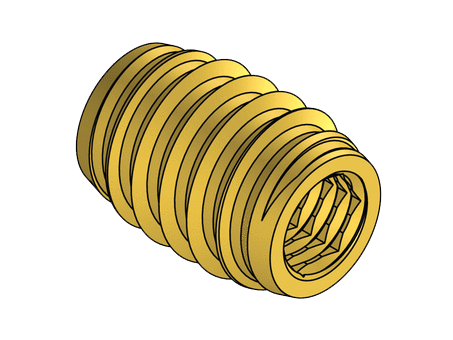

IVH

Brass threaded insert to be screwed in, without head

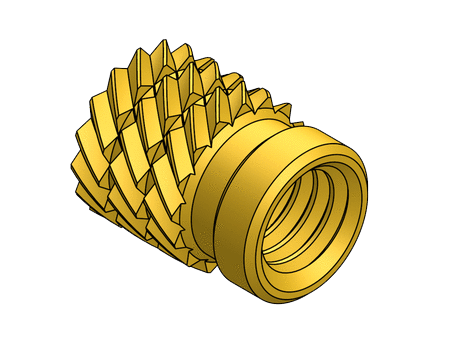

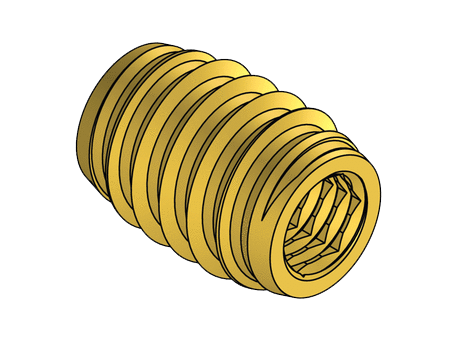

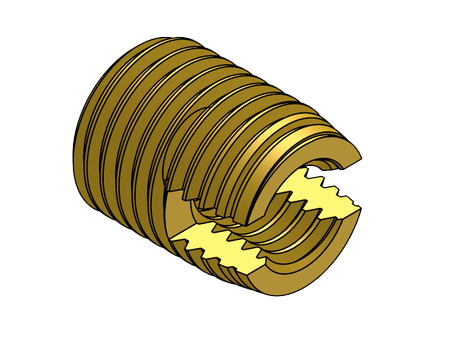

IV2

Threaded insert without head, for screwing – available in brass, steel or stainless steel

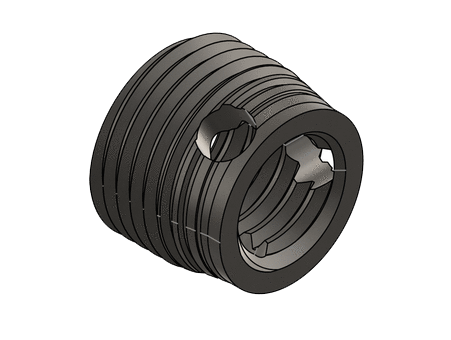

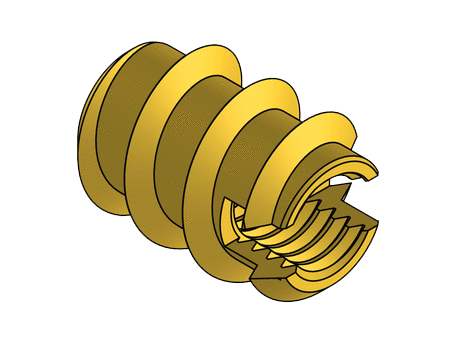

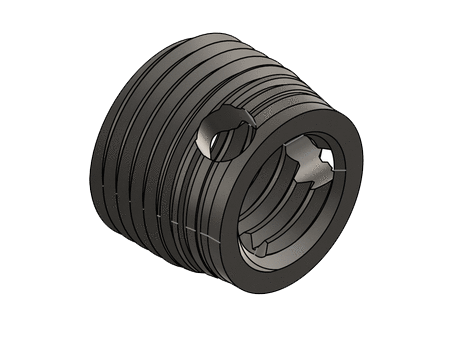

IV7

Steel or stainless steel threaded insert for screwing

IV8

Threaded insert to be screwed in, made of steel or stainless steel

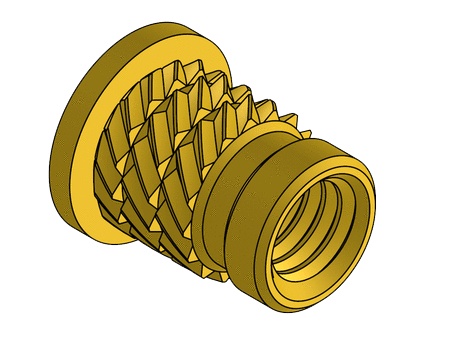

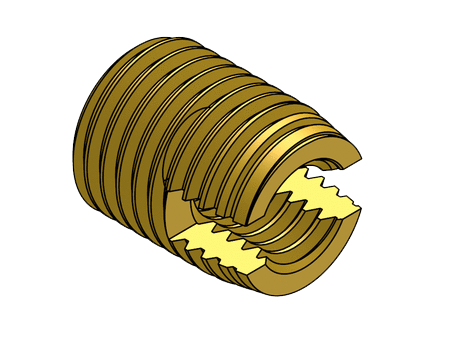

IV9

Threaded brass insert for thermoset PU foams and soft materials like softwood

Suitable

Suitable  Conditionally suitable

Conditionally suitable  Not suitable

Not suitable

Values are indicative. Each material is specific and has its own characteristics.

Contact us for advice

on choosing your insert

Do you have a technical or commercial question?

You can also write to us or call us.

Post-Molding Screw-In Inserts

Robust threaded fastening after molding or machining

Post-Molding Screw-In Inserts for Plastics, Light Alloys, Wood, and Foams

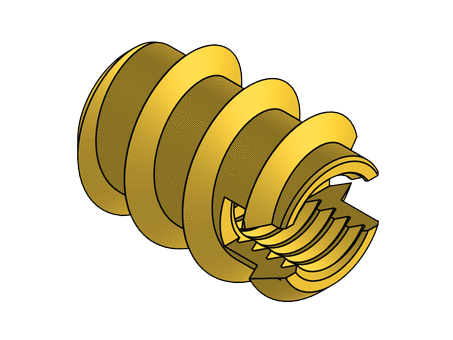

Post-molding screw-in inserts are used to provide a reliable and durable thread after the part has been manufactured, without the need to integrate the insert during the injection phase. They are mechanically inserted into the material thanks to their external thread, ensuring strong and lasting fastening in thermoplastics, thermosets, light alloys, softwoods, or polyurethane (PU) foams.

SECAM offers a wide range of screw-in threaded inserts made of brass, steel, or stainless steel, designed to meet requirements in strength, corrosion resistance, and material compatibility. This technical solution is suitable for both high-volume industrial applications and small series or prototypes.

Why choose a post-molding screw-in insert?

- Quick and easy installation in pre-molded, machined, or extruded parts

- Perfect for repairs or modifications of existing parts

- Can be installed manually or with automated screwdrivers

- Excellent pull-out and torque resistance

- Reduces molding constraints associated with in-mold inserts

Thanks to their optimized geometry, these inserts ensure excellent mechanical anchoring in many materials, while allowing for repeated threaded fastening (assembly/disassembly) without damaging the part.

SECAM’s Range of Screw-In Inserts

SECAM has developed several models of screw-in inserts, with or without head, in various materials and finishes. Here’s an overview of the available products:

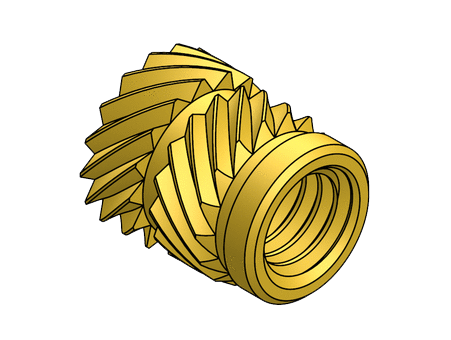

IVK – Brass screw-in threaded insert with head

The IVK model features a wide head that provides surface support and prevents over-insertion. It ensures better stress distribution and is ideal for soft plastics and low-density materials.

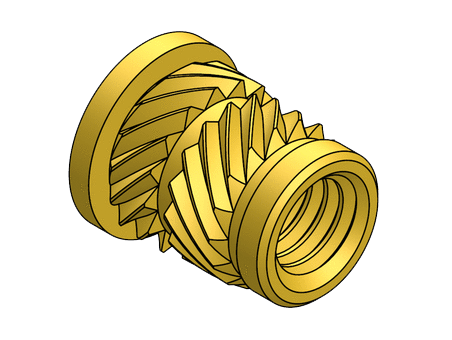

IVH – Brass screw-in threaded insert without head

The IVH insert is a headless model that sits flush in the material. It is ideal for aesthetic assemblies or thin-wall areas.

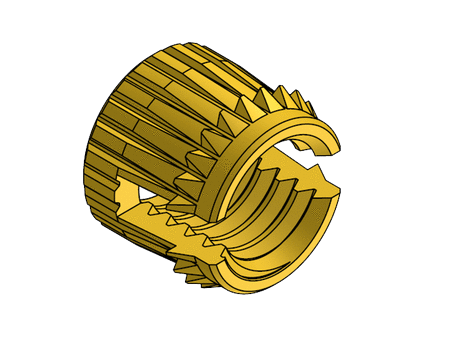

IV2 – Screw-in insert without head, available in brass, steel, or stainless steel

The IV2 series is available in several materials to meet corrosion or conductivity requirements. Its knurled cylindrical shape ensures a strong grip in technical plastics or soft metals.

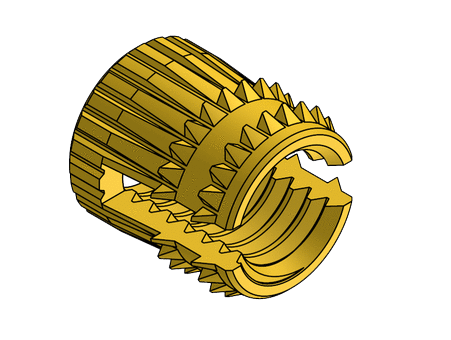

IV7 – Screw-in threaded insert in steel or stainless steel

Designed for demanding applications, the IV7 insert provides high mechanical strength. The stainless steel version is perfect for humid or aggressive environments.

IV8 – Screw-in insert in steel or stainless steel

A variant of the IV7, the IV8 model features a specific geometry that facilitates its installation and improves grip in low-density materials.

IV9 – Brass threaded insert for PU foams and softwoods

The IV9 is designed for soft substrates such as polyurethane foams and softwoods. Its aggressive geometry enables secure screwing without damaging the support.

Other Post-Molding Insert Solutions

In addition to screw-in inserts, SECAM also offers several alternatives for post-molding applications depending on your project’s constraints:

IEC – Short brass expansion insert

IEL – Long brass expansion insert

These inserts expand using an internal screw, ensuring strong anchorage in plastic materials. Ideal for parts requiring frequent disassembly.

IP1 – Headless brass press-in insert

IP2 – Brass press-in insert with head

Press-in inserts are installed through mechanical force, either manually or with a press. A quick and cost-effective solution without the need for heat.

IU1 – Headless brass ultrasonic insert

IU2 – Brass ultrasonic insert with head

Designed for ultrasonic or heat-set installation, these inserts are embedded into thermoplastics using dedicated machinery, which melts the surrounding material to form a reliable mechanical bond.

Selection Guide for Post-Molding Inserts

Choosing the right insert depends on multiple factors:

- Type of base material: ABS, PP, PA, POM, wood, aluminum, PU foam…

- Desired installation method: screwing, pressing, ultrasonic or expansion

- Part accessibility: visible side, bore diameter, depth

- Mechanical stress: torque, pull-out force, vibration resistance

- Corrosion resistance or technical environment constraints

Our team will assist you in identifying the most suitable solution for your needs.

Technical Inserts Designed for Industrial Applications

SECAM provides recognized technical expertise in the design and supply of threaded inserts for all your assembly applications. Our inserts are manufactured under strict quality and precision standards, ensuring perfect repeatability for series production.

Whether you’re in the automotive, electronics, medical, furniture, or other industries, we help you integrate a fastening solution that is high-performing, reliable, and cost-effective.

Need advice on our screw-in inserts?

Not sure whether to use a headed or headless insert? Looking to reinforce a thread in plastic or wood? Contact the SECAM team for tailored support. With stock availability and our in-house engineering office, we can quickly provide standard or custom inserts for your prototypes or production batches.

Ensure the reliability of your assemblies with SECAM’s post-molding inserts.

Contact Us

Do you have a technical or commercial question?

Leave us your contact details so we can get back to you.

You can also write to us or give us a call.

FAQ – Overmolded Inserts and Fastening Solutions for Plastics

What is an overmolded insert?

An overmolded insert is a threaded or smooth metal component placed into a mold prior to plastic injection. The molten plastic then flows around the insert during molding, creating a strong and precise mechanical bond. This process ensures a fully integrated, durable, and reliable fastening solution without requiring post-processing. Overmolded inserts are ideal for plastic parts that require a strong metallic thread.

What are the advantages of overmolding an insert?

Overmolding offers perfect integration of the insert into the plastic part with no secondary operation required. It ensures excellent axial and radial retention, improves aesthetics (flush or hidden), and eliminates the stresses associated with post-molding installation. It is an ideal solution for large-scale production, technical parts, or applications requiring high reliability.

Which materials are compatible with overmolded inserts?

Overmolded inserts are typically made of brass, steel, or stainless steel and are compatible with a wide range of thermoplastics (ABS, PA, PP, POM, etc.). Compatibility between insert and material must be verified based on processing temperature, plastic flow behavior, and mechanical requirements. SECAM can support you in this analysis.

How to choose between an overmolded insert and a screw-in insert?

The choice depends on your manufacturing process and constraints. Overmolding is recommended for high-volume production or parts requiring long-term durability. Screw-in inserts offer more flexibility, ideal for small series, repairs, or already molded parts. SECAM provides a selection guide to help determine the best solution for your needs.

Are there different shapes of overmolded inserts?

Yes. SECAM offers cylindrical, hexagonal, knurled, slotted, or grooved inserts—with or without head. Each geometry is designed to maximize mechanical retention based on the plastic material and expected forces. For special requirements, custom-designed inserts can be developed.

Can inserts be overmolded in technical or reinforced materials?

Yes, but it requires inserts that withstand higher molding temperatures and higher injection pressures. Reinforced materials (such as glass-filled plastics) require exceptional pull-out resistance. SECAM offers dedicated inserts with reinforced knurling or grooves for such demanding applications.

Do you offer custom-designed overmolded inserts?

Yes. In addition to our standard range, we design inserts based on your technical specifications. Our in-house engineering team supports you in developing the ideal insert for your mold, plastic material, and application environment.

Discover all our inserts for plastics, light alloys, and wood

SECAM has been your partner for over 50 years in the design and industrialization of your inserts for plastic, light alloys, and wood. We have a complete range of over 300 items available in stock.